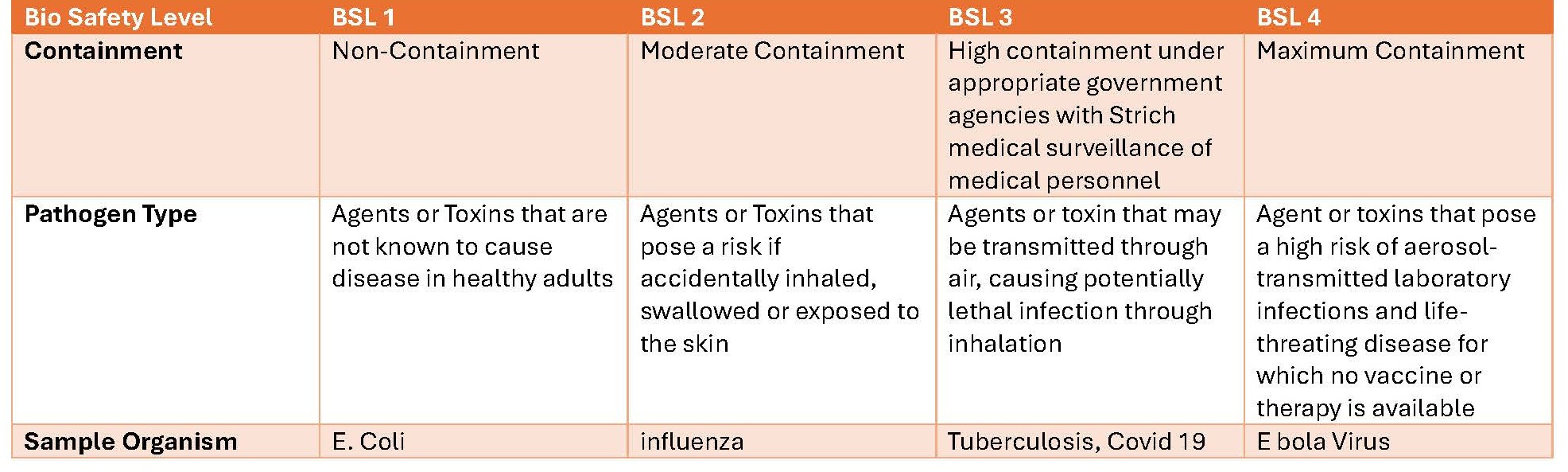

In carrying out activities in the laboratory, laboratory personnel are not free from the dangers of biological agents. Without proper handling, dangerous biological agents can also be released and enter the environment. For this reason, appropriate biosafety steps and practices are needed to protect laboratory personnel, prevent the release of dangerous pathogens, and ensure environmental safety. Biosafety Level (BSL) provides a framework for categorizing laboratories based on the risks associated with the agents handled. There are four biosafety levels that are distinguished based on infectivity, disease severity, level of spread, and activities carried out in the laboratory. Each biosafety level regulates the microbiological practices, safety equipment, and facility security required in relation to handling agents

Bio Safety Laboratory (BSL)

Level 3

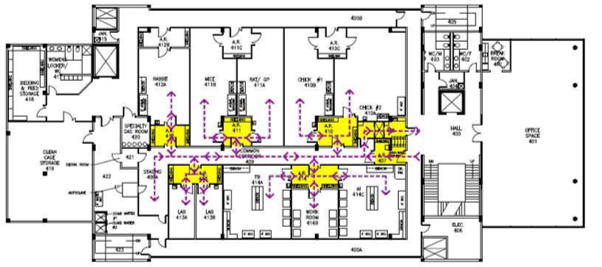

Sample of BSL 3 Multilabs Layout

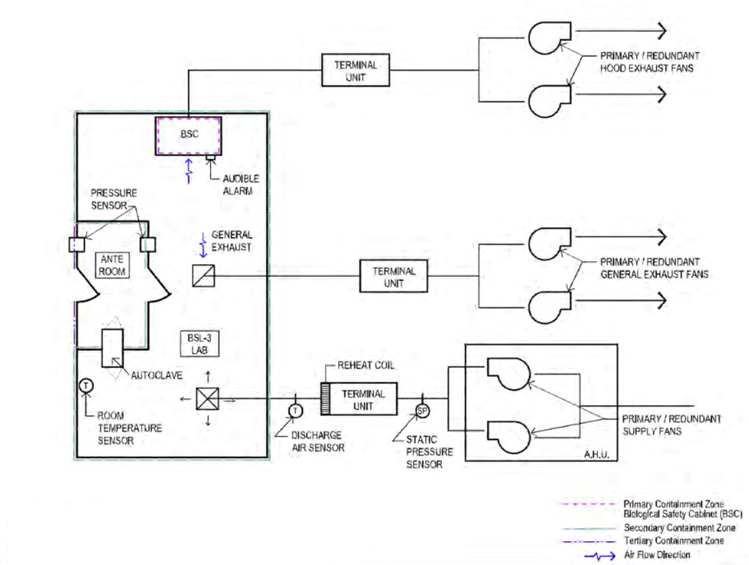

Typical BSL3 Alarming Schematic

Modular System Partition

Apart from stationary laboratories using brick walls, we can also create modular forms using sandwich panel systems, up to mobile laboratories. Modular wall systems have many advantages for laboratories, including:

Bio Safety Laboratory

Walls and Ceiling

- Reinforce structure wall and ceiling panel suitable for negative pressure

- Sealed Airtight and chemical resistant

- Radius coving are installed at wall-to-wall, wall-to-ceiling.

Doors

- Lockable, airtight and self closing doors

- Entrance doors are interlock with emergence manual override

- Emergency exit.

Floor

- Slip, abrasion and chemical resistant PVC/epoxy floor

- All covered corner wall joint are carefully cut, formed and sealed

- Top coving strip, around the inner perimeter of the walls, is carefully sealed with RTV sealant

Pass through Box

- Made of stainless steel

- With mechanical interlocking

- Installed with UV sterilizer

Autoclave

•Double door autoclave is installed in the main laboratory for sterilization

•Double door interlock

•Unidirectional material flow from main laboratory to outside

Shower Room

•Double door with interlock system to keep the negative pressure

•Optional : Air Shower, Water Shower, Chemical Shower, Mist Shower

Water Decontamination System

Waste Decontamination Systems (EDS) are a critical component of facilities that handle potentially hazardous biological waste. These systems are specifically designed to treat effluents—liquid waste or waste—produced by biological laboratories, medical facilities, and industrial processes, before they are released into the environment. Biological laboratories, in particular, produce waste that may contain genetically modified organisms, viruses, bacteria, and other dangerous pathogens. The primary purpose of an EDS is to neutralize or eliminate these dangerous pathogens, chemicals, and contaminants, thereby preserving public health and the integrity of the environment.